Weaving | Knitting

MES systems are especially significant in Weaving | Knitting due to the large number of machines for particular challenges - the precise and reliable real-time recording of production data such as running and set-up times, for example, is of particular importance. The long lead times require the most precise material requirements planning possible. inteos® is the ideal partner to meet these challenges due to the textile know-how of its developers.

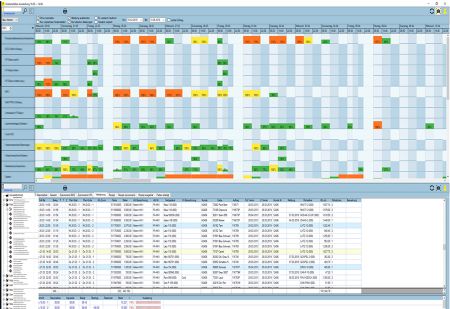

With inteos® , all applications of a modern weaving/knitting production are integrated, from the production overview to planning & dispograph to quality management. Of course, all production stages can also be operated "mobile" - with our handheld solutions "weaveLINK" and "knitLINK"!