NEWS | GoLive at Mey | August 2023

A GoLive during ongoing operations is always an interesting challenge, especially when third-party applications are also in use. We are therefore pleased to have implemented the process for Mey Bodywear without any interruptions.

NEWS | ITMA 2023 - Summary| July 2023

We were very happy about their visit at the ITMA in Milan, which ended on Friday! Take a look at our summary!

NEWS | inteos® Virtual Factory | May 2023

Fancy a little textile walk? Let's take a tour of our Virtual Factory, which will go live in time for ITMA after almost a year of development work and is already available in video form on our homepage. more...

NEWS | New customer Triumph International | May 2023

We are proud to announce a particularly pleasing development in May 2023: Triumph International, the world-renowned manufacturer of underwear, is now one of inteos®' customers.

NEWS | New customer Tolnatext | January 2023

Renowned textile firm, Tolnatext, based in Hungary, has partnered with us to enhance its preparation and weaving processes with our MES solution inteos®. We are looking forward to our collaboration!

NEWS | New customer Textilveredlung Keller | October 2022

We are pleased to welcome a new customer also in October 2022, Textilveredlung Keller from Mößingen.

NEWS | Lingerie manufacturer Mey relies on inteos® | March 2021

We are pleased to announce that we have gained another renowned customer - the Mey company, located in Albstadt. Mey GmbH & Co. KG manufactures high quality day and night clothing and lingerie.

NEWS | Visit to Hugo Boss and reshoring insights | December 2024

Impressions from the vendor event at Hugo Boss and a brief digression into the topic of ‘reshoring (in the textile industry)!

NEWS | Presentation in Chemnitz: ‘Data as fuel for global connectivity and transparency - with inteos®’ | September 2024

Halo Business Partner Klaus Kreutzberg had the opportunity to speak at the IVGT in Chemnitz about the ‘megatopic’ of ‘digitalisation’ and the special role of ERP systems such as inteos® in this process.

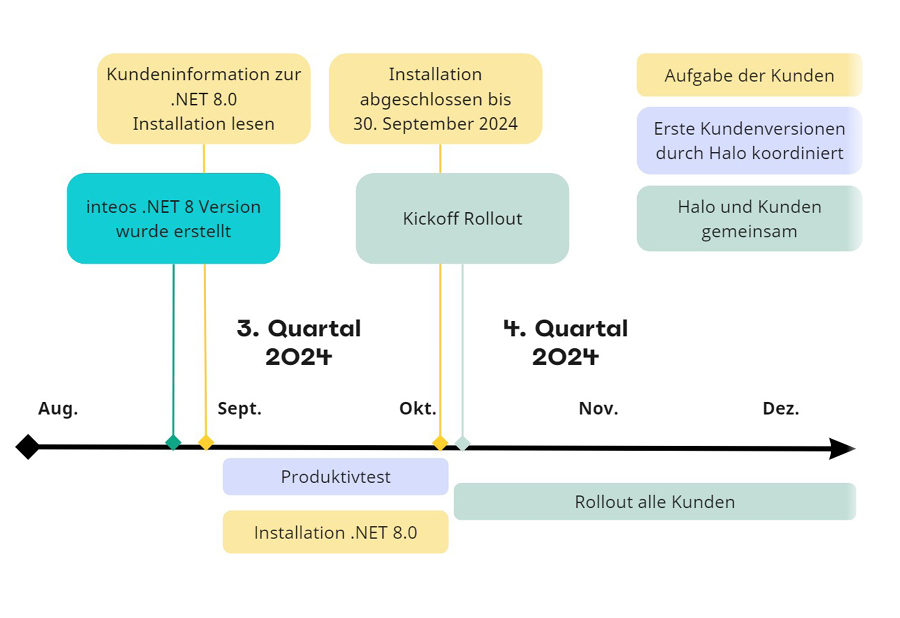

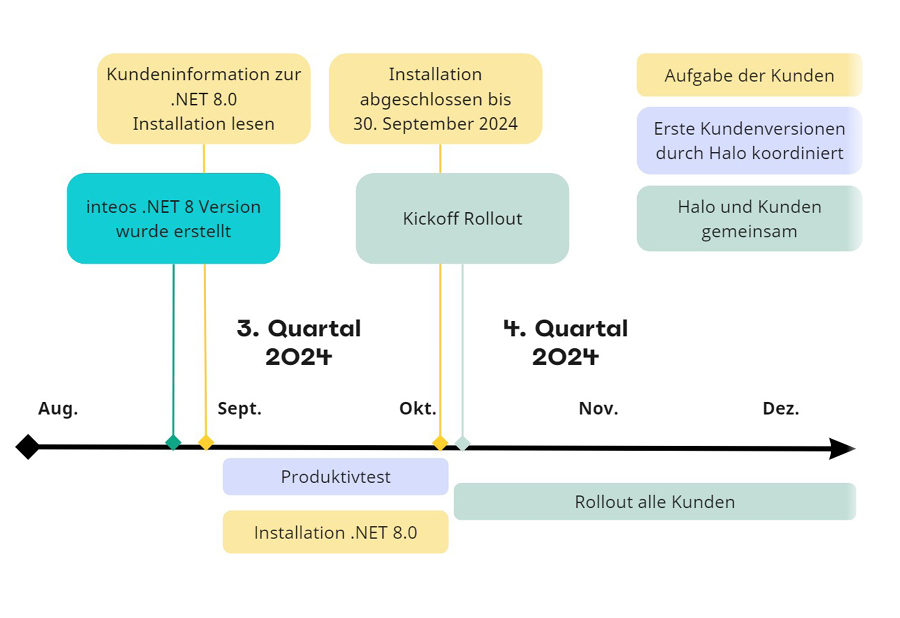

NEWS | inteos® and .NET 8.0 | August 2024

Our existing customers will soon be informed about the upcoming migration to .NET 8.0. But what exactly is behind this step and what are the benefits? Let's take a direct look at our latest developments relating to inteos® - with information directly from our research and development department.

NEWS | Case Study - Drechsel | July 2024

Together with ICTRAC RTLS, we have succeeded in realising real-time goods carrier location at Drechsel Textilveredlung TVD.

NEWS | Case Study - Keller | June 2024

Following the successful ERP project, Textilveredlung Keller GmbH went live with inteos® in just 10 months.

NEWS | Techtextil 2024 | June 2024

We would like to thank all our customers and visitors for the remarkably high level of interest and the inspiring discussions at our stand.

NEWS | Successfully completed apprenticeship | March 2024

We congratulate Alexander Bildstein on successfully completing his apprenticeship as an application developer.

NEWS | GoLive at Mey | August 2023

A GoLive during ongoing operations is always an interesting challenge, especially when third-party applications are also in use. We are therefore pleased to have implemented the process for Mey Bodywear without any interruptions.

NEWS | ITMA 2023 - Summary| July 2023

We were very happy about their visit at the ITMA in Milan, which ended on Friday! Take a look at our summary!

NEWS | inteos® Virtual Factory | May 2023

Fancy a little textile walk? Let's take a tour of our Virtual Factory, which will go live in time for ITMA after almost a year of development work and is already available in video form on our homepage. more...

NEWS | New customer Triumph International | May 2023

We are proud to announce a particularly pleasing development in May 2023: Triumph International, the world-renowned manufacturer of underwear, is now one of inteos®' customers.

NEWS | New customer Tolnatext | January 2023

Renowned textile firm, Tolnatext, based in Hungary, has partnered with us to enhance its preparation and weaving processes with our MES solution inteos®. We are looking forward to our collaboration!

NEWS | New customer Textilveredlung Keller | October 2022

We are pleased to welcome a new customer also in October 2022, Textilveredlung Keller from Mößingen.

NEWS | Lingerie manufacturer Mey relies on inteos® | March 2021

We are pleased to announce that we have gained another renowned customer - the Mey company, located in Albstadt. Mey GmbH & Co. KG manufactures high quality day and night clothing and lingerie.

NEWS | Visit to Hugo Boss and reshoring insights | December 2024

Impressions from the vendor event at Hugo Boss and a brief digression into the topic of ‘reshoring (in the textile industry)!

NEWS | Presentation in Chemnitz: ‘Data as fuel for global connectivity and transparency - with inteos®’ | September 2024

Halo Business Partner Klaus Kreutzberg had the opportunity to speak at the IVGT in Chemnitz about the ‘megatopic’ of ‘digitalisation’ and the special role of ERP systems such as inteos® in this process.

NEWS | inteos® and .NET 8.0 | August 2024

Our existing customers will soon be informed about the upcoming migration to .NET 8.0. But what exactly is behind this step and what are the benefits? Let's take a direct look at our latest developments relating to inteos® - with information directly from our research and development department.

NEWS | Case Study - Drechsel | July 2024

Together with ICTRAC RTLS, we have succeeded in realising real-time goods carrier location at Drechsel Textilveredlung TVD.

NEWS | Case Study - Keller | June 2024

Following the successful ERP project, Textilveredlung Keller GmbH went live with inteos® in just 10 months.

NEWS | Techtextil 2024 | June 2024

We would like to thank all our customers and visitors for the remarkably high level of interest and the inspiring discussions at our stand.

NEWS | Successfully completed apprenticeship | March 2024

We congratulate Alexander Bildstein on successfully completing his apprenticeship as an application developer.inteos® | the product

With inteos® you are relying on ERP and MES software that has been specially designed for the special challenges of the textile industry. inteos® is completely integrated and covers all manufacturing stages in textile production - from the fibre to the product, from the quotation to the invoice.

With our many years of textile experience, with inteos® we do not offer you an isolated software package, but a complete solution tailored to your needs for optimising your production processes.

Halo | the company

More than 35 years of experience make us a competent partner for the development and application of fully integrated IT solutions.

We're intimately familiar with the requirements and particularities of textile production processes. Based on this knowledge we develop customised ERP and MES solutions for your company!

Industry 4.0 for the textile industry

Everybody talks about Industry 4.0 – for good reason: complete process digitization from the design phase to the finished product is the only way forward.

Since our inception, we have specialized in the digitization of corporate processes — Industry 4.0 has been our guiding principle for 35 years!

That is why you are always one step ahead of technological development with the fully integrated ERP and MES solution from inteos®. Take a tour of our Virtual Factory for a glimpse into the future of textile production!